R&D Ability

研发能力北京聚菱燕塑料有限公司,凭借日本四日市研发基地以及中国中石化提供技术支持,着力于本土研发实力的提高,已由传统材料供应商转型为汽车轻量化绿色科技解决方案提供商。公司自成立以来,一直将技术创新置于企业发展的首要地位,基于客户要求为客户提供一系列的创新产品。聚菱燕公司生产的汽车用聚丙烯改性产品,不仅赋予了产品较好的性能,而且为环境保护提供了可持续发展的方案。

Beijing Ju-Ling-Yan Plastic Co., Ltd., with its R&D base in Yokkaichi, Japan and Sinopec technical support, has laid stress on improving its local R&D strength and successfully shifted from a traditional auto material supplier to a solution provider for green auto lightweight technology. Since its establishment, the Company has always been putting technological innovation at the top of corporation development, and providing customers with a series of innovative products pursuant to their requests. The Company’s PP modified products for automobiles not only give the excellent performance for products, but also render sustainable development plans for environmental protection.

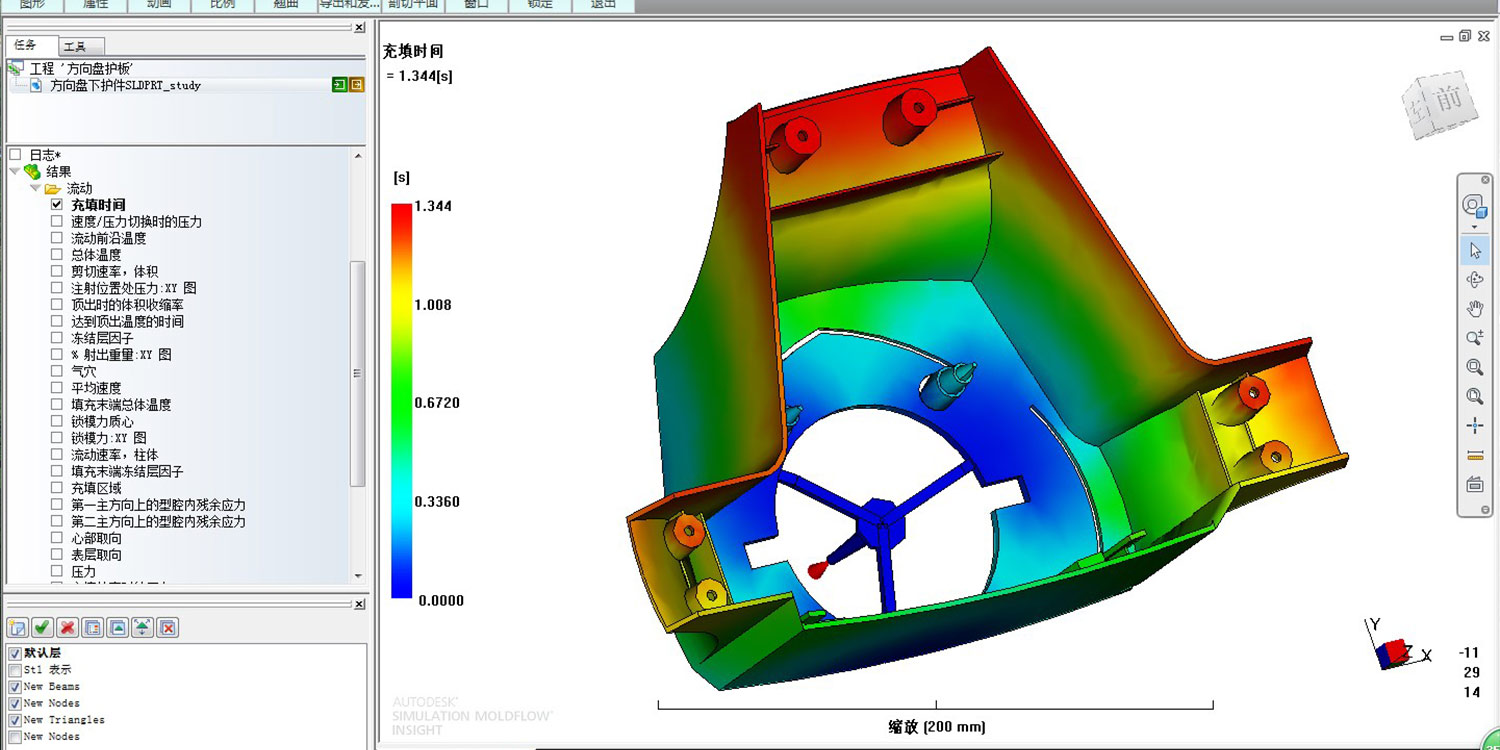

通过对基础原料的生产技术(催化、工艺)、配方技术、成型加工以及分析评价技术的多方位研发,在汽车轻量化、低VOC低气味、节能减排、高性能以及降低成本方面做出对应,为客户提供全方位的汽车轻量化绿色科技解决方案。

After multi-directional R&D in the aspects of production technology (catalysis and process) of basic raw materials, formula technology, polymer processing, analysis and evaluation technology, the Company has made corresponding achievements in auto lightweight, low VOC & low odor, energy saving & emission reduction, high performance and cost reduction. Accordingly, the Company is able to provide customers with a full range of green auto lightweight technology solutions.PP Development Technology for Automobiles

汽车用PP开发方面的技术评估技术

Evaluation Technology优秀材料

Latest Material配合技术

Formula Technology复合技术

Composite Technology构造控制

Structural Control聚合催化技术

Polymerization Catalyst Technology分子构造设计

Molecular Structure Design